Meet the Makers: Selecting the Perfect Piece of Wood for Every Table Top!

Today, you have a unique opportunity to meet the makers! From conception to creation to production to installation, each table top at Old Dominion Furniture Co. gets its start as a single piece of wood in the factory.

Today, you have a unique opportunity to meet the makers! From conception to creation to production to installation, each table top at Old Dominion Furniture Co. gets its start as a single piece of wood in the factory.

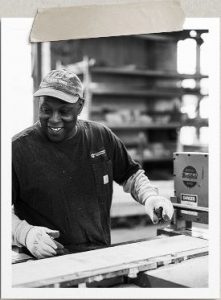

It is the job of traveling Gospel singer, Bernard, to set the initial benchmark of quality for every wood table top produced.

Bernard first started working for Old Dominion in 1975. He would go to class in the morning and work a full-time shift in the factory after school. He is proud of the joy and growth his position has brought him. “I wouldn’t get out of bed, for 45 years, for a job I hate.”

Bernard is a self-taught, yet expert, lumber grader and is responsible for sorting, selecting and grading each piece of lumber that comes into the Old Dominion Furniture Co. building. His commitment to his craft is a key component to the high standards of quality.

So you might be asking yourself; how does the dimensioning department work?

Step 1: Grade

Sorting, selecting and grading raw lumber sets the quality benchmark

Step 2: Chop

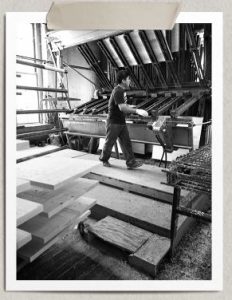

Chopping raw boards to specific lengths based on table top dimensions

Step 3: Rip

Ripping the sides of raw boards for clean, straight edges, ideal for adhering boards together

Step 4: Glue

Positioning and gluing boards based on grain pattern, to create raw table top panels

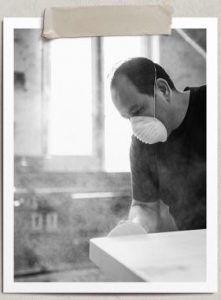

Step 5: Sand and Size

Sanding, sizing and edging table top panels to meet order specifications.

Upon completion of each piece, the dimensioning department inspects all table tops before releasing them to the Finishing Department for stain and sealer.

We hope to share more installments of Meet the Makers in the future, as we find it interesting to learn about different aspects of the manufacturing process.

No Comments